Sales Department: 0552-3825188 0552-3825333

Accessories Department: 15955260712

Company Fax: 0552-3825255, 3825200

CNG Department: 13865028777 13865066118

After-sales service: 0552-3825155 0552-3825156

Company Address: No. 2581, Shuangdun Road, Huaishang District, Bengbu, Anhui Province

Company email: zdysj@126.com ahzdysj@126.com

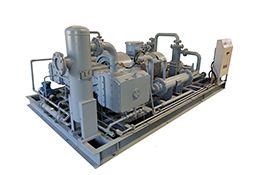

Introduction to the working principle and characteristics of hydrogen compressor

Hydrogen compressors can be piston type, diaphragm type, centrifugal type, etc. Hydrogen compressors are important equipment in drying positions. They must be able to work reliably during rectification and installation, which is the focus of electrical maintenance work. Understanding the working principle of hydrogen compressors can help prevent misjudgments and quickly resolve problems when encountering problems during maintenance work, thus minimizing unplanned equipment shutdowns.

The hydrogen compressor uses compressed air to pressurize low-pressure hydrogen. The pressure of low-pressure air is converted into the pressure of high-pressure hydrogen through the hydrogen compressor, and the pressure is infinitely adjustable. The pressure of the pressurized hydrogen can be adjusted by adjusting the pressure of the driving gas source. It can compress low-pressure hydrogen and can be used for laboratory hydrogenation reactions and hydrogen circulation experiments.

Hydrogen compressor has the following characteristics:

(1) The working pressure range is large. Different types of pumps can be used to obtain different pressure areas. The output pressure can be adjusted accordingly by adjusting the input pressure. It can reach extremely high pressure, 300Mpa for liquid and 90Mpa for gas.

(2) Wide flow range. For all types of pumps, only 1Kg of air pressure is required to work stably. At this time, a very small flow rate can be obtained. Different flow rates can be obtained by adjusting the air intake.

(3) Easy to control, from simple manual control to complete automatic control.

(4) Automatic restart: no matter what causes the pressure in the pressure-maintaining circuit to drop, it will automatically restart to replenish the leakage pressure and maintain a constant circuit pressure.

(5) Safe operation, gas driven, no arc or spark, can be used in dangerous places.

(6) Energy saving can reach 70% because no energy is consumed by maintaining pressure.

Previous: Other applications of oxygen compressors

下一条: Liquid inlet protection device for liquefied gas compressor

Related Industry Knowledge

- Hydrogen compressor equipment structure and preparations before start-up

- What are the factors to consider when choosing an air compressor?

- What is a compressor?

- The correct operation method of air compressor

- Take you to understand the use of vinyl chloride compressors

- Analysis of Factors Affecting Production Capacity of Hydrogen Compressor

- The difference between biogas compressor and natural gas compressor

- Protective measures for hydrogen compressor and its auxiliary systems

- The composition structure of the air compressor

- How to choose a good air compressor?

- Other applications of oxygen compressors

- How to properly maintain the air compressor

- The role of PLC in natural gas compressors

- Analysis of the Leakage Causes of Nitrogen Compressor

- Troubleshooting methods for carbon dioxide compressor

- Advantages of air compressor frequency conversion energy saving

- Reversing steps for carbon monoxide compressor

- Control method of natural gas compressor

- Is it possible to remove water from an air compressor?

- How to install the air compressor without oil leakage?