Sales Department: 0552-3825188 0552-3825333

Accessories Department: 15955260712

Company Fax: 0552-3825255, 3825200

CNG Department: 13865028777 13865066118

After-sales service: 0552-3825155 0552-3825156

Company Address: No. 2581, Shuangdun Road, Huaishang District, Bengbu, Anhui Province

Company email: zdysj@126.com ahzdysj@126.com

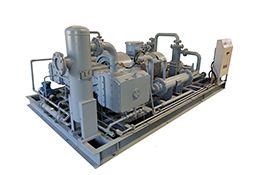

Fire extinguishing system for air compressor

The air compressor active fire fighting system is a mining area active fire fighting equipment with simple structure, simple operation and high safety function. It is mainly composed of temperature detector, sound and light alarm, sensor, controller, nozzle, medicine bottle, perfluorohexanone fire fighting flame retardant, etc. It can monitor the fire danger in real time around the clock, put out the fire in the first time, prevent the fire from spreading, and improve the safety function of air compressors, transformers, distribution rooms, chambers, belt conveyors, cable shafts, etc.

With the in-depth development of coal mining operations, the mining level is getting deeper and deeper, the gas content is increasing, the ground temperature is rising, and the production system is becoming more and more complicated. The spontaneous combustion of mining air compressors (referred to as air compressors) has become a dangerous problem that needs to be solved urgently for safe production in coal mines. However, the traditional rescue method has untimely exploration and response, delayed rescue, and low efficiency, which can no longer meet the needs of efficient development of air compressors. The effective prevention and control of air compressor fires by the air compressor active rescue system has become the primary choice for safe production in mining areas.

Air compressor oil is the main cause of air compressor spontaneous combustion. Whether the oil's ignition point meets the requirements and whether the anti-oxidation function meets the standards, the oil is constantly changing under pressure, and when the temperature is 80 degrees and 100 degrees, the gasification amount of the compressor oil will be different. The gasification amount at 100 degrees is 10 times that of 80 degrees. Therefore, the greater the gasification amount of the compressor oil, the more carbon deposits are generated. Carbon deposits are constantly affected by the compressor temperature and will continue to heat until flames are generated.

The necessity of air compressor automatic rescue system for safe production in chamber mining areas:

(1) Complete effective fire detection at the early stage of fire and reduce the fire safety risk of air compressor.

(2) Rapid fire exploration and pipe network spraying firefighting technology to complete efficient firefighting in mining areas.

(3) Perfluorohexanone resuscitation agent quickly vaporizes and absorbs heat to cool down, suffocating and resuscitating, effectively preventing the fire from rekindling.

Previous: Application range of air compressor

Related News

- How to adjust the air volume of the air compressor?

- The status quo and development trend of compressor technology

- Knowledge about daily maintenance of air compressors

- Reasons for lack of compressor displacement

- What are the common faults of compressors?

- Maintenance of natural gas compressor

- Safe use of vinyl chloride compressors

- Analysis of several common failures of dimethyl ether compressor

- The structure and characteristics of vinyl chloride compressor

- How to maintain the vinyl chloride compressor?

- Application range of air compressor

- The use of oxygen compressor

- Working principle of biogas compressor

- Use of air compressor

- Introduction of Nitrogen Compressor

- Reasons why the air compressor pressure is not enough

- Working principle of hydrogen compressor

- Technological innovation and application prospects of oxygen compressors

- What is the working principle of carbon monoxide compressor?

- Precautions for using nitrogen compressor